Seed Preparatory Equipment and Their Working

Seed preparatory equipment plays a vital role in the oil extraction industry by preparing oilseeds for further processing in solvent extraction or oil expelling units. Proper seed preparation is crucial, as it directly affects the efficiency of oil recovery, the quality of extracted oil, and the overall plant productivity. Our advanced seed preparatory equipment is designed to ensure uniform processing, reduce wear and tear, and optimize the extraction process.

1. Seed Cleaning Machine

The seed cleaning machine removes impurities such as dust, stones, metal particles, and leaves from raw oilseeds. This step is essential to protect downstream machinery from damage and to ensure consistent processing. The machine uses a combination of sieves, blowers, and magnetic separators to achieve effective cleaning.

2. Destoner

The destoner separates heavier foreign materials like stones, glass, and metal fragments based on weight difference. As oilseeds are generally lighter than these impurities, the destoner vibrates the seeds over a perforated screen, allowing heavier materials to settle and be removed separately.

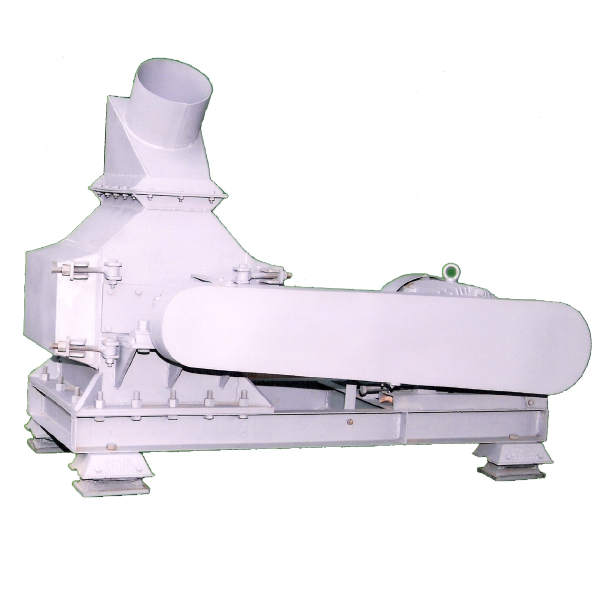

3. Dehuller or Decorticator

Some oilseeds, such as sunflower and cottonseed, contain outer husks or shells that must be removed. The dehuller or decorticator cracks the seeds to separate the kernel from the hull. The machine consists of a rotating drum or rollers that apply mechanical pressure, breaking the husk without damaging the kernel. The hulls are then removed using an aspiration system or gravity separation.

4. Cracker

The cracker is used to break the seeds into smaller particles to increase the surface area, which enhances solvent penetration during extraction. It uses two corrugated rollers that rotate in opposite directions to break the seeds uniformly without producing excessive fines or powder.

5. Cooker or Conditioning Machine

After cracking, the seed particles are conditioned by heating and adding moisture in a steam-jacketed cooker. This step helps in softening the seed structure, denaturing proteins, and adjusting moisture levels to ideal values for flaking or expelling. Proper cooking increases oil yield and reduces energy consumption during extraction.

6. Flaker

The flaker presses the cooked seeds into thin flakes, further increasing surface area for efficient oil extraction. The machine consists of two heavy-duty rollers that compress the material into uniform flakes of 0.3 to 0.4 mm thickness. These flakes are ideal for solvent extraction, as they allow better solvent access to the oil cells.

7. Expander (Optional)

In some processes, an expander is used to gelatinize starches, deactivate enzymes, and pre-extract some oil. It uses high pressure and heat to form porous pellets, increasing extraction efficiency and reducing solvent usage.

In conclusion, our seed preparatory equipment is engineered for maximum performance, durability, and energy efficiency. By ensuring thorough cleaning, cracking, conditioning, and flaking of oilseeds, we set the stage for superior oil recovery and long-term operational reliability.